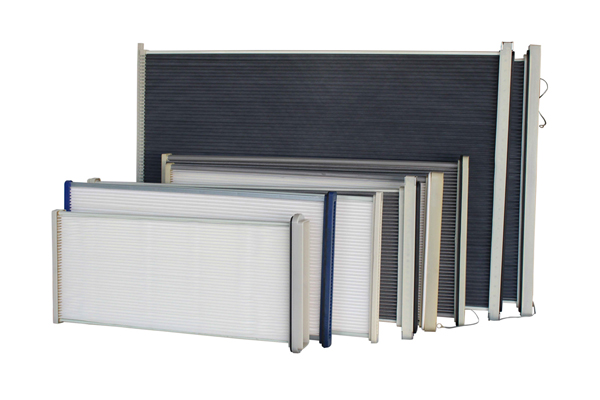

Independent R&D Filter Materials for Industrial Filter Cartridges

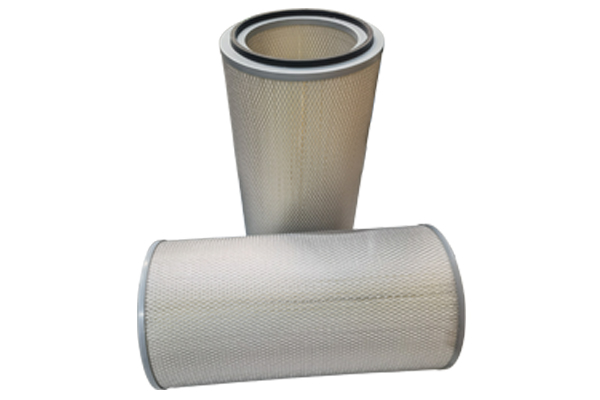

With the increasingly stringent environmental protection requirements, all of the industries pay more attention to the needs of ultra-low dust emissions. Due to the different characteristics of dust in different industries, the requirements for filter elements are different. As we all know, filter media is the core component of industrial filter cartridges. According to the different characteristics of dust and applications, Farrleey has independently developed unique filter materials. So what types of filter materials does Farrleey offer and what makes one different from another?

Independent R&D Filter Materials From Farrleey

Farrleey has researched and developed following materials for industrial filter cartridges, and each one of them has its applications, features, and benefits.

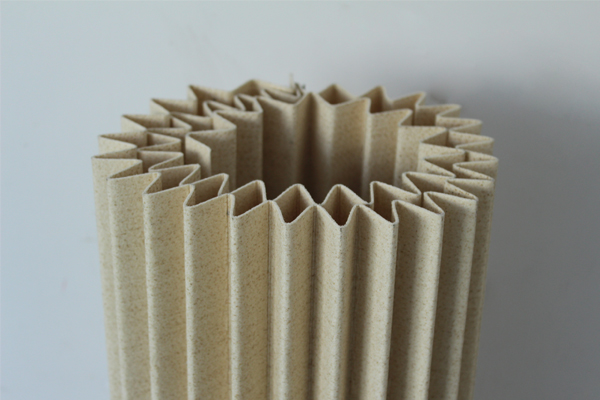

1.Pleatable Needle Felt

![]() Features

Features

The R & D team of Farrleey has developed needle felt filter materials that can be used for pleating, including polyester, PPS and Aramid. Compared to traditional filter bag, it can increase filter area, save space and easy to replace and install.

![]() Advantages

Advantages

- High air permeability– Pleatable needle felt provides high air permeability, compare to spun bond polyester, its air permeability is same as filter bag material.

- Reach the low emission standard of 10mg– These materials are also helpful in reaching low levels of emissions. For example, it will assist your industry in reducing the emission level up to 10 mg.

- Superior dust holding capacity– One of the most important benefits of using these industrial filter cartridges that are made of pleatable needle felt is their superior dust holding capacity. The effectiveness of filtering can be fully realized.

- High working temperature– Developed PPS and Aramid felt for high working temperature, Max. temperature is 220℃.

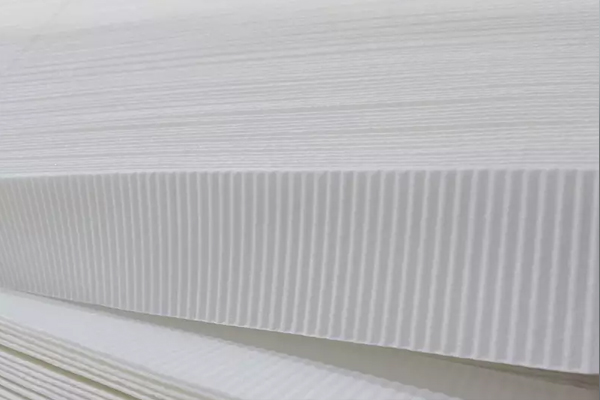

2.Polyester Corrugated PTFE Membrane Flame Retardant

![]() Applications

Applications

In terms of the Polyester Corrugated PTFE Membrane Flame Retardant, it is exclusively available with Farrleey, which guarantees perfect filtration. This filter material is specially used forlaser cutting and welding fume industries.

![]() Features

Features

It is a two-component material developed independently by Farrleey, which can be a thermally fused PTFE membrane.

![]() Advantages

Advantages

- Extreme efficiency– These corrugated filter materials provide extreme efficiency up to the level of 95 % @ 0.3 um. On the other hand, other brands can hardly reach up to 80 % for the same particle size.

- Low resistance– Due to the low-pressure drops in these corrugated filter materials, air permeability reaches up to 200L/㎡.s in these devices. This is a significant achievement of Farrleey at a time when other brands’ filters can reach air permeability to 150 L/㎡.s hardly.

- High tensile strength

CD>450N/5CM

MD>270N/5CM

Dry: 250/150N

Wet:60N/5CM - Excellent flame retardancy

3.Polyester Carbon Fiber Blended Corrugated Media with PTFE Membrane

![]() Application

Application

The unique filter material is widely used in new energy lithium battery, aluminum processing, graphite and other flammable & explosive industries.

![]() Features

Features

They are made of carbon fibers blended with corrugated media,and have the properties of anti-static PTFE membrane flame-retardant.

![]() Advantages

Advantages

- Extreme efficiency– These filter materials purify the gasses as much as possible to make the purge cleaner. For particle size of 0.3um, these filters have efficiency up to 95%.

- Low resistance– With an air permeability of 200L/㎡.s, industrial filter cartridges that are made of these materials provide low resistance to incoming fluid hence making the process faster.

- High Tensile Strength

CD>450N/5CM

MD>270N/5CM

Dry: 250/150N

Wet: 60N/5CM - High moisture resistance– By providing high moisture resistance capabilities, Farrleey ensures that these filter media have a long life, which helps industries save money in the long run.

- High explosion-proof level

- Excellent flame retardancy

Benefits of Choosing Farrleey

Farrleey provides innovative solutions in filtration technologies and keeps industrial operations safe and secure. When you choose Farrleey as your filtration partner, you sign up to use world-class products in your industries.

Conclusion

Farrleey is dedicated to providing filtration solutions to varying industries. While many filter manufacturers are available out there, Farrleey has a distinction of serving almost all the industries with industrial dust collectors, including but not limited to the cement industry, food & beverage industry, pharmaceutical industry, and metalworking industry.