Farrleey’s Dust Cartridge Filter Applied in Food Processing Industry

In the 21st century, the modernized food processing industry is still one of the most rapidly growing industries. Breakaway from the traditional workshop into the automatic factory with thousands of assembly lines; the food has been produced at an astonishing rate. Due to the expansion of the production scale, the stringent requirements for the level of hygiene and safe atmospheres not only determines the quality of food product but also get rid of the major product safety issues to the health of the employee.

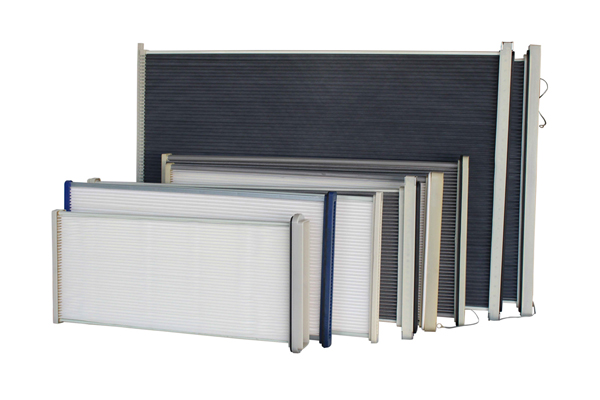

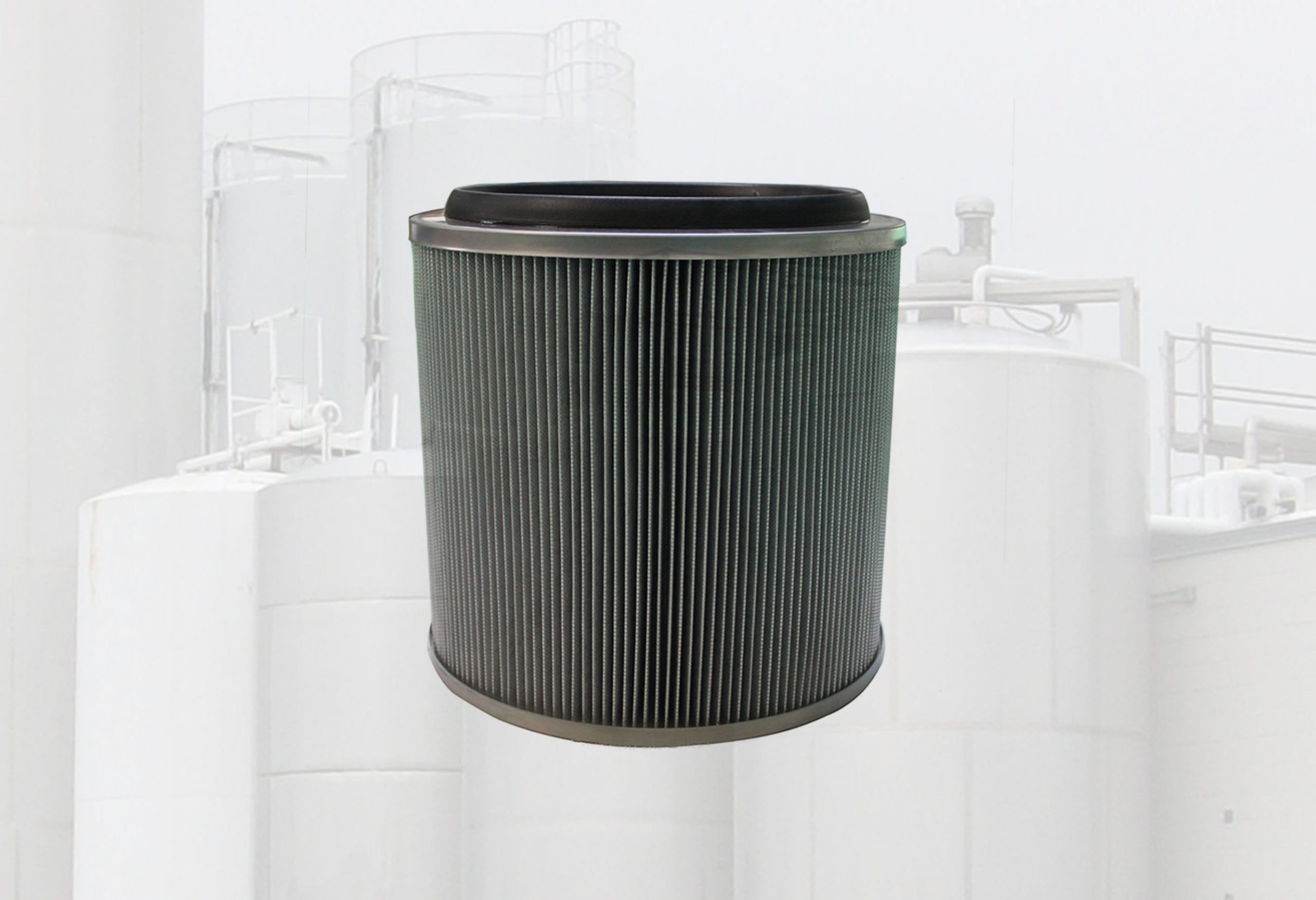

Food industries such as cereal ingredients, spices, raw grains, flours, corn starches, sugars, and dairy have sanitary requirements and food handling regulations. According to these regulations, Farrleey has developed various dust cartridge filters that can be applied to meet specific needs in the food processing industry. The pleated filters are widely used in bulk & material processing, conveying, packing, storing, etc. In addition, the strong R & D department of Farrleey has developed specific filter materials for the food industry that has been issued with an SGS certificate.

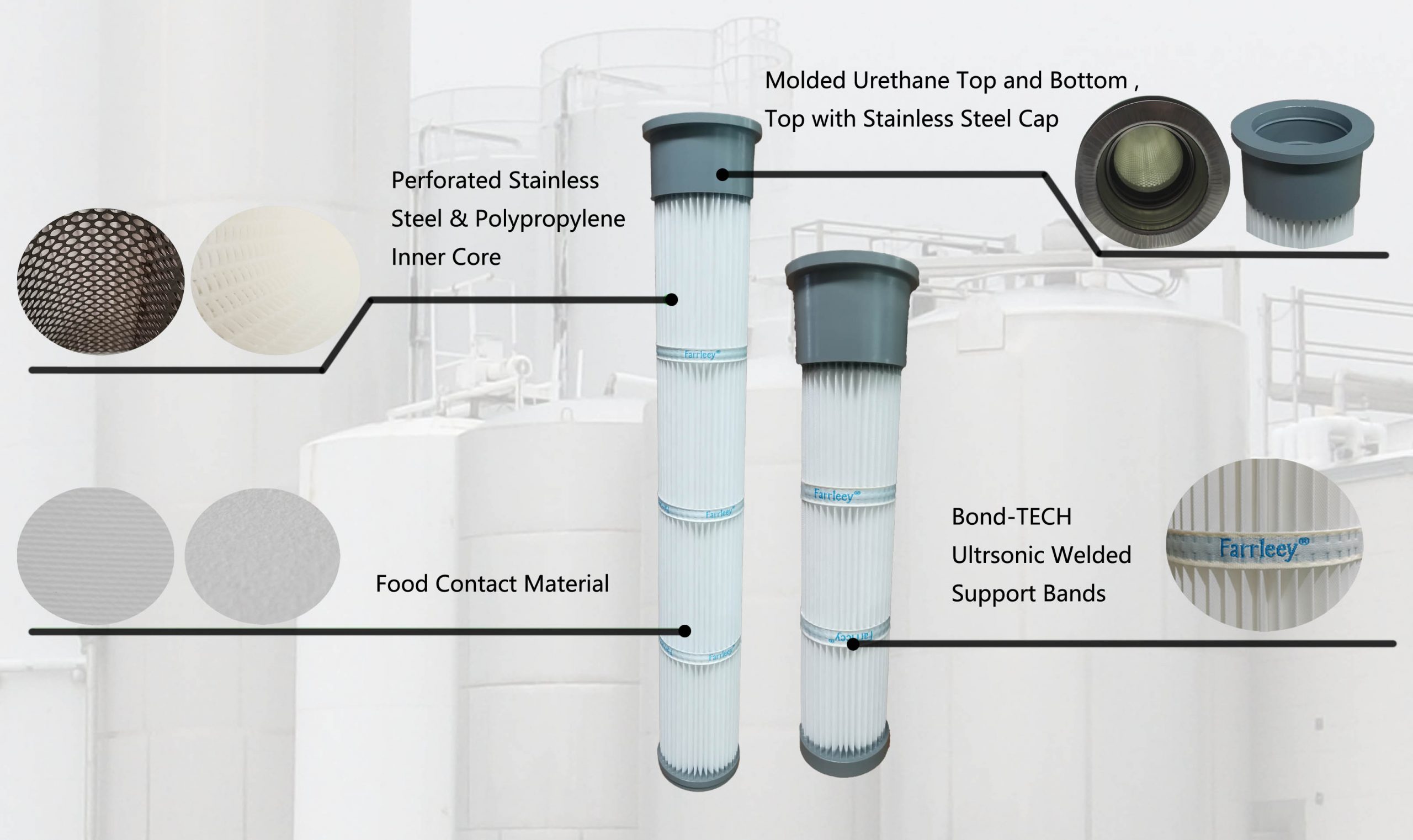

Key Components in Dust Cartridge Filter

Farrleey’s pleated filter cartridge has leading performance and well reputation in the industry. The key components that affect the performance of the food industry dust collection process have been discussed with the following points.

- Materials of End Caps

It’s important to choose the correct end caps material to meet food-grade requirements. Not only SUS304 material caps, but Farrleey also supplies you with PU and molded polymer reinforced end caps, which passed food contact certifications.

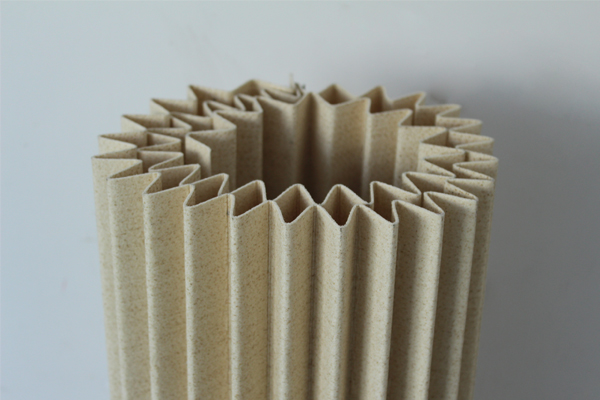

- Materials of the Filter

The dust particles generated in the food processing are very fine; when product contamination must be minimized, it has high requirements on the filtration efficiency of the filter material. High-performance PTFE membrane is laminated on spun-bond polyester and needle felt, filtration efficiency on very fine particles <0.3 microns @ 99.99%, excellent performance on moist or agglomerative dust. This independently developed filter material has been issued with SGS certification.

- Materials of the Inner Mesh

The 304 stainless steel and PP (polypropylene) were applied to the inner mesh of the filter cartridge, which ensures high mechanical strength of the inner structure and high corrosive resistance to heat the acid chemicals.

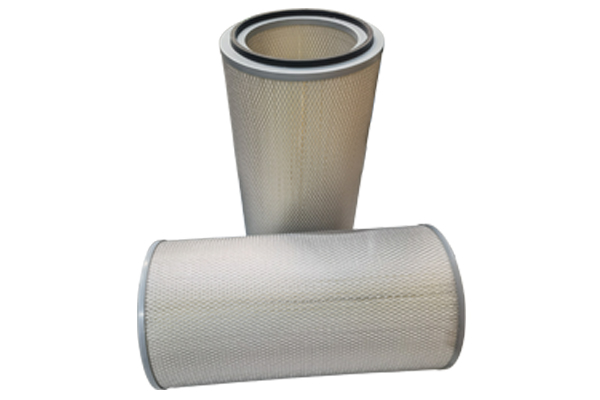

Farrleey’s Dust Cartridge Filter in Dairy Industry

Our product has been widely applied in the dairy industry’s top brands in New Zealand, including Fonterra Co-operative Group, YASHILI, Oceania Diary, and Danone Nutricia. In real cases, the filter cartridge can be applied in the different manufacturing processes. Here is a detailed explanation of the dust cartridge filter applied in the milk powder industry.

The environment for dairy manufacturing has a dust-free requirement. Any impurities will result in product pollution. Our filter cartridge using PU glue has perfectly solved this issue and ensured the manufacturing environment meets the requirement.

During the washing, cooking, mixing, and packing process, there will be a high chance that particles enter the manufacturing atmosphere, which will lead to a major threat to the health of the operators and the quality of the product. In addition, because milk powder is in the form of particles, it is very easy to spread and float in the air, which may cause dust explosion since the factory is a relatively closed area. Our dust cartridge filter with dust collection device has an important role in maintaining a standard working condition in every process and protecting the safety of the employee.

Conclusion

With high-tech laminated dust cartridge filter material, our product has high dust collection rate, high structure strength, long product life span, and high energy-saving efficiency. Choosing Farrleey as your ideal industrial filter cartridge supplier will not let you down. Contact us now for more information about industrial dust collectors.

About Farrleey

Farrleey was established in 2007 in Guangzhou. Not only in the food industry, but Farrleey’s dust cartridge filter has also been widely applied in different industries, including cement & mining, metalworking, pharmaceutical industry, and other industries that have dust removal requirements. As an ultra-low emission retrofit solution service provider, we have long historical development and experience in the metallurgical manufacturing industry.

Now Farrleey is one of the pioneers and leaders in the dust cartridge filter industry. We are the leading company in drafting and determining the industry standard. We have been awarded outstanding achievements in technological innovation by the Ministry of Industry and Information Technology. Our product makes a great contribution to energy saving and carbon reduction that answers the trend of environmental protection.