Welding Fume Cartridge Filter

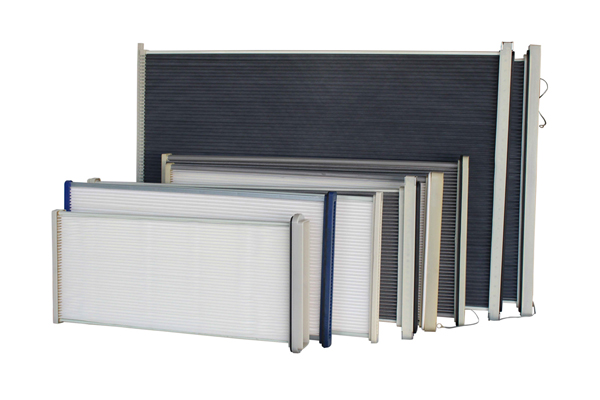

Aiming to become the global leader in cleaning and energy-saving technology solutions, Farrleey has been focusing on the research and development, manufacture, sales of high-quality environmental protection equipment and filter elements since 2007. The product line varies to dust collection filters, pleated filter bags, filter bags, and other products.

Recently, Farrleey has launched a newly designed extreme efficiency dust filter cartridge, which is special for the welding fumes in welding industry, including plasma laser cutting, shipbuilding, automotive, metal processing, welding smoke, thermal spray industry, and etc.

Features of New Arrival Extreme Efficiency Dust Filter Cartridge

The surface filtration of cartridge dust collectors is much more efficient than the previous dust collectors, which greatly reduces the emission of harmful gas and is therefore widely used. The new industrial filter cartridges used in industrial cartridges have improved dust removal efficiency mainly by using new low resistance filter media. The PTFE coating is also flame retardant, making it suitable for filtering gases with combustible particles, reducing the possibility of explosion and combustion.

Filter Material Property Comparison

The new arrival dust filter cartridge is made of high-quality material with mature processes, different from other brands in the market. Here are some comparisons.

- Extreme Efficiency and High Tensile Strength Material

Farrleey’s new arrival dust filter cartridge can reach the filtration rate of 95%@0.3um. Cellulose and synthetic fibers are generally used as filter media in the market. Considering that the exhaust gas of the welding industry may contain metal dust particles, Farrleey uses polyester material, which is more resistant to wear and tear and has higher strength.

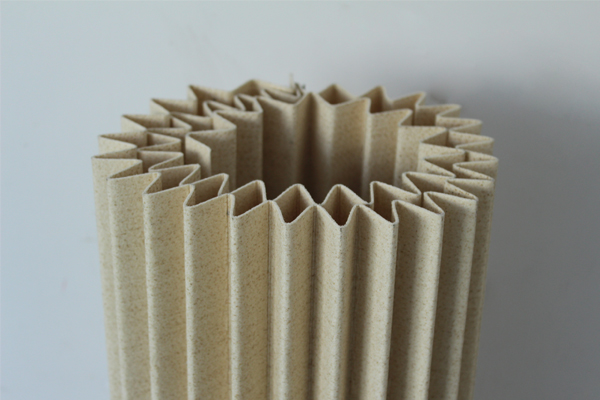

By taking advantage of polyester’s high strength and moderate flexibility, the filter element material is adopted in the corrugated treatment, which increases the contact area between the cartridge and the airflow to improve the filtration effect.

- Low Resistance and Excellent Flame Retardant

Except for the need to use a polyester material with efficient adsorption capacity, the surface treatment of the filter media is also significant. Unlike the Nano fiber treatment on the market, the new dust filter cartridges use thermally fused PTFE membrane. It not only reinforces the thickness of the material, making it more wear-resistant. At the same time, it also increases the air permeability of the material. The higher the air permeability of the material, the lower the resistance to airflow and the higher the filtration efficiency is. The air permeability of the new industrial filter cartridge reaches 200L/㎡.S, which is 33.3% higher than other brands on the market.

What’s more, the filter material has a higher working temperature than the PTFE membrane, which can reach 100℃, making it more suitable for the welding fumes from laser cutting industries.

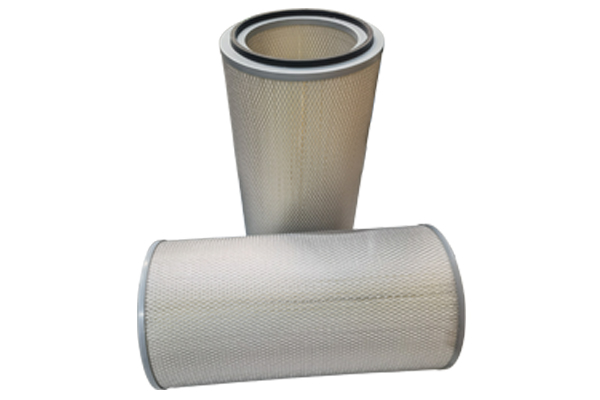

Dust Collection Filters Structure Analysis

Farrleey industry filter cartridge series improves the filtration efficiency and extends the service life by optimizing the structure, focusing not only on the selection of high-quality filter media, but other factors listed below.

- The end cover of the dust collection filter is made of a high-quality electrolytic plate, which has good anti-corrosion and anti-rust performance.

- The reinforced spiral mesh of the dust collection filter has greater strength than the common filter mesh in the market. There is an even gap between the inner mesh and the filter material, so there is no rub with the filter material.

- The filter is made by low hardness and high strength closed cell rubber seal to ensure the airtightness of the filter cartridge.

- Super strong adhesive is used to avoiddebonding and cracking, which ensures the service life of the dust filter cartridge and the safety of use under high load.

Conclusion

Farrleey has more than six production lines and many product series with an annual production capacity of over 1.2 million pieces. Since our establishment, Farrleey has carefully studied each industry’s different dust removal needs and strived to offer our clients better and more efficient dust removal cartridges and filters. Because we know that there are different kinds of environmental protection dust removal processes, efficient and durable dust collector equipment has a profound effect on the productivity of enterprises, the health of workers, and the surrounding environment.

Contact Farrleey now and let us provide you with customized and cost-effective dust removal solutions to maximize your investment in comprehensive economic strength.