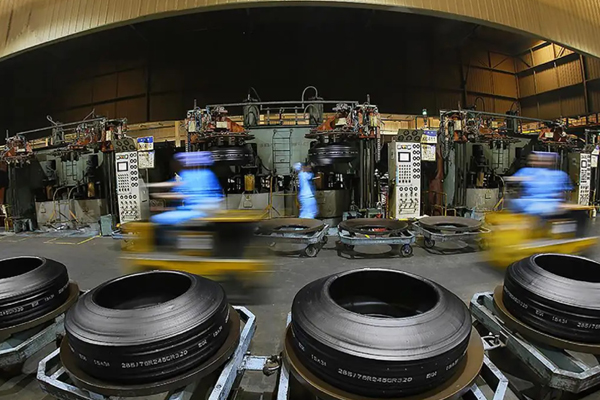

Dust characteristics of the foundry workshop: many dust points, scattered, and widely distributed; high dust concentration; strong dust pecking; heavy dust ratio.

The process layout of the dust removal system should be used to remove dust on site (combining dust collector, fan and dust-raising equipment to collect and recover dust on site. This method is compact, simple, convenient to maintain, and energy-saving.) and system dust removal (combined Combine the suction ports of several dust-raising equipment with the same dust nature and close distance into one system at the same time).

Two-stage dust removal process should be adopted: cyclone dust collector + filter bag/cartridge dust collector to increase the service life of the filter bag and filter cartridge.

When cartridge dust collector is used at the point with high dust content, the filter cartridge should be installed vertically, and the folding number and folding depth should not be too large.

When designing the dust removal pipeline, while ensuring the dust-catching ability of the hood, it is necessary to prevent the molding sand from being carried into the dust removal pipeline by the airflow, which can not only reduce the pipeline friction, but also prevent the dust accumulation in the pipeline and the dust filter material from being rubbed by the dust particles. damage.

When designing the exhaust hood, the influence of the surrounding environment on the exhaust effect should be considered, especially when the exhaust hood is located near the entrance of the workshop, the influence of the draft should be fully considered, and the wind speed of the hood should be appropriately increased or corresponding technical measures should be taken.

Including:

Vibration shakeout and dust removal

Screening, conveying, unloading and dust removal

Crushing, winnowing and dust removal

Dust removal of sand mixer