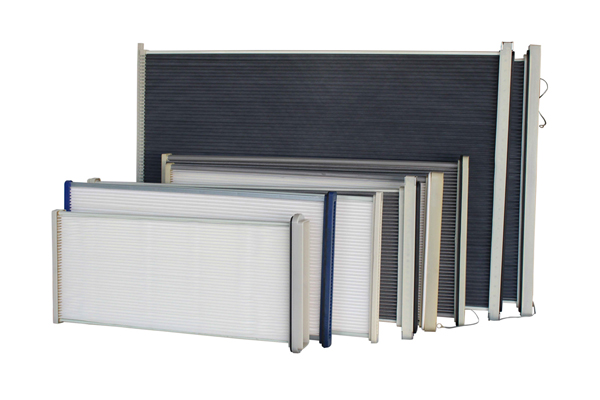

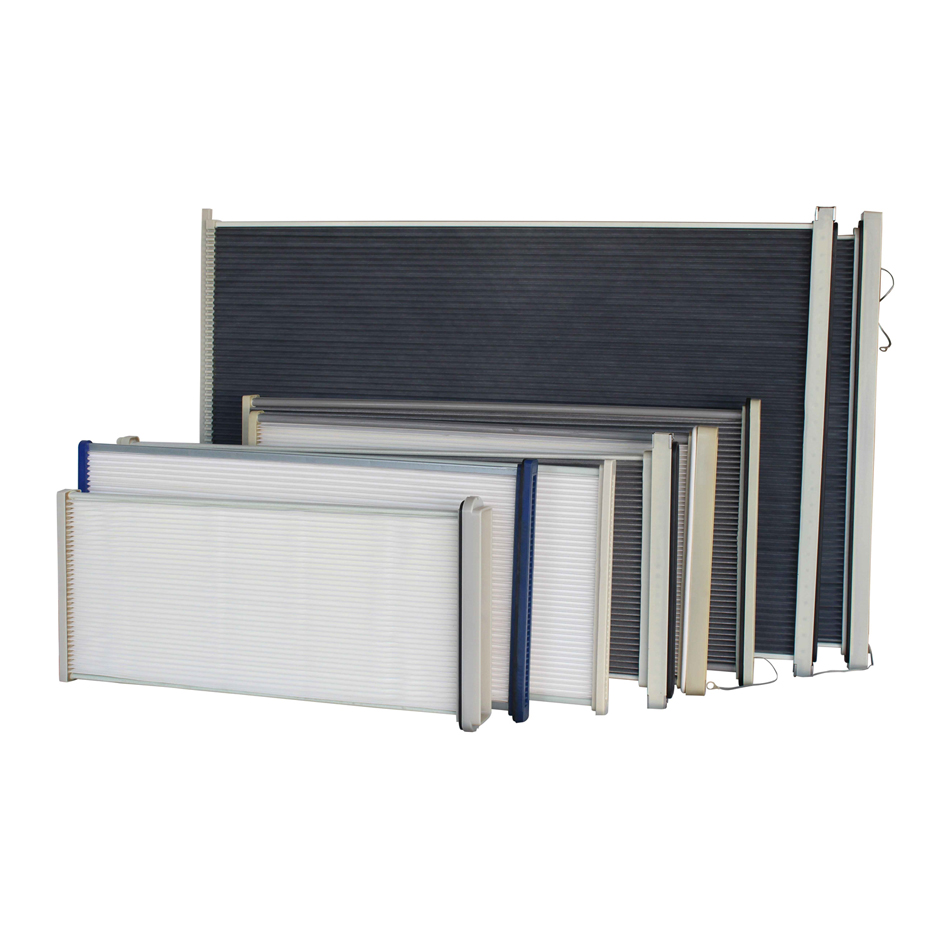

TANNASON® Flat Panel Filter

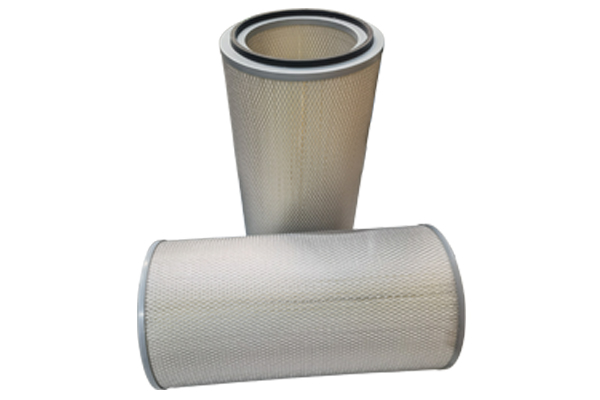

With increased local and global attention being given to the control of air pollution, containment of nuisance dust in all industrial applications is becoming increasingly important. Since its inception, the dust collector has offered companies the ability to effectively capture airborne particles from an air stream. Whether toxic or not, containment of particles is necessary to provide a healthy and clean work environment. At present most of the dust collector suppliers mainly choose traditional cylinder cartridge filter and filter bag as filter element, flat panel filter is a innovative and upgrade filter element.

How Does TANNASON® Flat Panel Filter prior to traditional filter bag and filter cartridge?

Here introducing the features and advantages:

1.Compact Type Design

The compact type design require smaller space, but increase filtration area, it’s 5 times than round filter bag and twice than flat filter bag in the same volume space. As the volume of the industrial dust collector needs to be minimized to fit the flat panel filter, the whole equipment cost is greatly reduced.

2.Prolong Service Life

- Withthe same air volume, the filter air velocity drops by 2-5 times, and the erosion and wear of the dust loading airflow on the filter material is significantly reduced;

- Integrated design, withoutcage, no friction and wear between cage and filter material;

- The unique design of the filter cartridge will not cause damage caused by collision and friction with each other.

Therefore, under the same working conditions, the flat panel filter service life will prolong.

3.Superior Dust Cleaning Effect

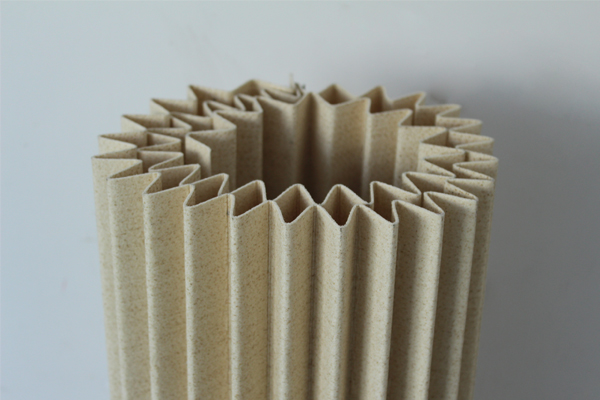

- The dust is easy to harden on theflat filter bag’s surface. The pleated design of the panel filter is not easy for dust to harden.

- Cylinder filter cartridgeshave many pleats, and wider pleat depth, and it is not easy to clean the dust.

- The flat panel filterhas wide pleats, and the pleats are wide, which is easy to clean and replace

In the case of the same air volume, the flat panel filter’s filtration air velocity is reduced by 2-5 times, the pressure difference between the front and rear of the filter material is greatly reduced, and the dedusting is easier.

4.Lower Differential Pressure

Under the same air volume, the filter velocity of flat panel filters drops by 2-5 times, and the pressure discrepancy between the front and rear of the filter material decreases significantly. Therefore, the dust cleaning pressure is reduced to only 3 to 3.5kg when the bag filter is generally ≥ 5kg. In addition, the dust cleaning cycle is longer and helps save compressed air energy consumption.

5.Flexible Installation Methods

For bag filters, it can only be installed vertically. The volume of equipment is bulky, difficult to install, and requires more space for installation. The installation of a panel filter is more flexible. It’s especially suitable for the harsh installation environment. It can be top-mounted, bottom-mounted, and side-mounted and can also be installed at special angles according to the different needs of customers.

6.Unique Venturi Design on the Head

The special Venturi-formed head design is another guarantee of dust cleaning effect.

7.Different Materials Meet Your Requirements

1)Spunbond Polyester & Needle Felt Material

2)Chemical Finish: Water & oil repellent, Anti-static coating, PTFE membrane

Applications of the TANNASON® Panel Filter

At present, the products have various applications, including the steel industry, foundry industry, cement industry, non-ferrous metal smelting industry, etc. In particular, it meets the needs of many enterprises to achieve ultra-low emissions without modifying the dust collector.

Conclusion

In the context of global low-carbon emissions, various industries need to choose suitable filtration products. Farrleey was established in 2007. We have been committed to providing various industrial filter cartridges to customers from all walks of life for more than a decade. For more information, please don’t hesitate to contact us.