Industrial Dust Collector Maintenance Tips: Keep Your Collector Running Efficiently

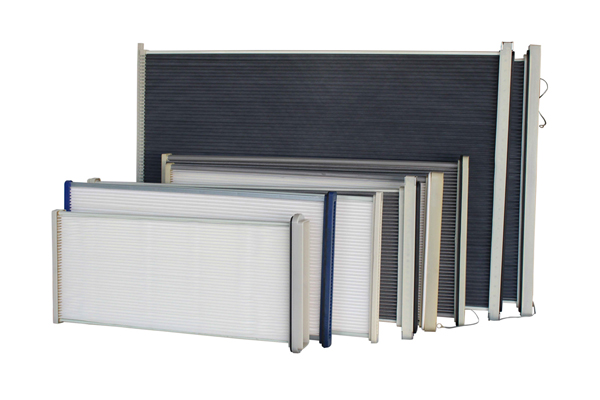

For health and productivity of employees, more and more companies are choosing to install industrial filters to capture dust and fumes in the air and create a clean space. The dust collection filter solves many of the problems of traditional dust collectors, with a faster filtration rate and better dust removal efficiency. At the same time, dust collector maintenance is a key step in ensuring the effectiveness of dust removal.

Why Is The Dust Collector Maintenance Needed?

Like other industrial machines, regular dust collector maintenance is inevitable for the dust collection filters to function properly. Arranging dust collector maintenance by timely replacement of components is a way to improve the efficiency of its dust collection and avoid the scrapping of the whole machine. In addition, dust collectors with poor performance often results in very high dust loads or inefficient cleaning. If not maintained, these problems can cause unexpected downtime and operating costs increase.

So, before you starting dust collector maintenance, Read these useful tips, which will offer a great help to avoid unexpected downtime or frequent filter changes.

.jpg)

6 Useful Tips Of Dust Collector Maintenance

Tips 1: Use The Correct Parts

Using the right parts is essential for the proper functioning of a dust collector. Whether it is a blower of the electric type or a dust filter cartridge without electricity, avoid to replace it with improper or with poor-quality parts when doing dust collector maintenance.

Tips 2: Remove Dust From The Hopper

Each part of the filter has its purpose. The hopper is not intended for dust collection and storage. Especially in the case that if some combustible dust is collected in the hopper, which might cause a fire or explosion hazard. Also, when carrying dust collector maintenance, the dust in the hopper should be cleaned to avoid it clogging the system and affecting the efficiency of dust collection filters.

Tips 3: Check Diaphragm Valves And Pipework

When installing or replacing a new industrial filter cartridge, it is advisable to check the diaphragm valve first and ensure that the cartridges inside are all clean. It is also important that the filter’s pipework is functioning properly. The National Fire Protection Association requires that the pipework upstream of the dust collector is protected. In the event of a fire, if the upstream pipework has been equipped with an isolation valve, it is useful to prevent the spread of flames through the inlet pipework.

Tips 4: Use The Correct Air Pressure

The air pressure is vital to the performance of dust collection filter and a key observation point at dust collector maintenance is . When the air pressure is too low, the cartridge tends to degrade and saturate quickly; on the contrary, if it is too high, the cartridge will be used up more quickly and require frequent replacement, as well as shortening the life-span of the cartridge and increasing costs. Therefore, during the dust collector maintenance, it is important to make sure the filter uses the correct air pressure.

Tips 5: Observe Pressure Drop

Another factor that affects the ability of a dust extraction system to capture dust is the pressure drop. As dust accumulates, some will penetrate the filter media and increase the pressure drop. So, when the airflow reaches a differential pressure, take care to replace the filter cartridge.

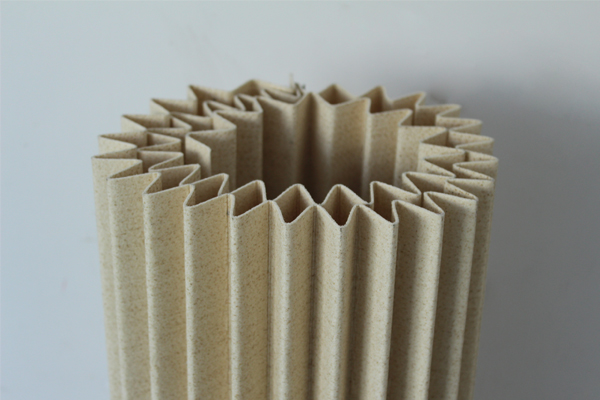

Tips 6: Check The Filter Media

The cartridge is the focal point of the dust collector maintenance. The industrial filter cartridge is the most important part of the dust collection filters and will directly affect the filtration efficiency. What cannot be ignored is regularly checking the dust collection situation of the dust filter cartridge.

These are all key tips for dust collector maintenance. However, inreal cases, sourcing efficient, durable dust collectors is the fundamental way to avoid frequent repairs and replacement of spare parts. Farrleey, an experience and trusted filter cartridge manufacturer, is committed to providing highly cost-effective filter cartridges and filter bags for different dust collectors in various industries.

Choose Farrleey As Your Trusted Filter Cartridge Supplier

If you are under industrial filter cartridges installation or replacement, Farrleey is the right place to purchase your ideal product. We have received a great reputation for being a trustworthy filter cartridge manufacturer and supplier through the years of our efforts. We have an extensive range of quality filter cartridges and filter bags suitable for different working conditions in different industries. Our industrial filter cartridges and bags guarantee superior performance with affordable prices. So, you will surely find the perfect component for your projects from us.