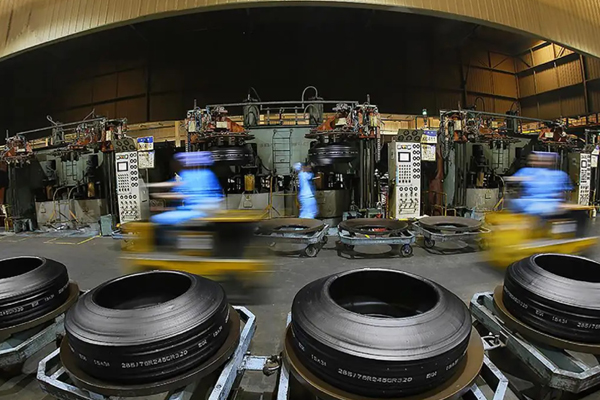

Mill production line is widely used in calcite, marble, limestone, barite, talc, kaolin, dolomite, wollastonite for dust collection, and the inlet dust loading is high.

High pressure difference will directly affect normal production and have a great impact on output and energy consumption. It is very important to control pressure difference within a reasonable range.

If the dust is easy to absorb moisture, the filter material should be treated with water and oil resistance.

The activated modification has a certain humidity, and the filter material should be treated with water and oil resistance.

The activation modification has a certain temperature, and the temperature resistance of the filter material should be considered.

According to the fineness of the product, select the filter material with suitable precision.

Using ordinary filter materials, ultra-fine powder will penetrate the filter material and enter the fiber. The resistance of the filter material rises quickly and the service life is short. The PTFE membrane material should be considered for eugenics.

The original baghouse has high pressure loss and frequent replacement of filter bags, which affects production. It is the best solution to replace filter bags with filter cartridges.

Large-scale ultra-fine dry powder processing of non-metallic minerals such as gypsum, feldspar and pyrophyllite.