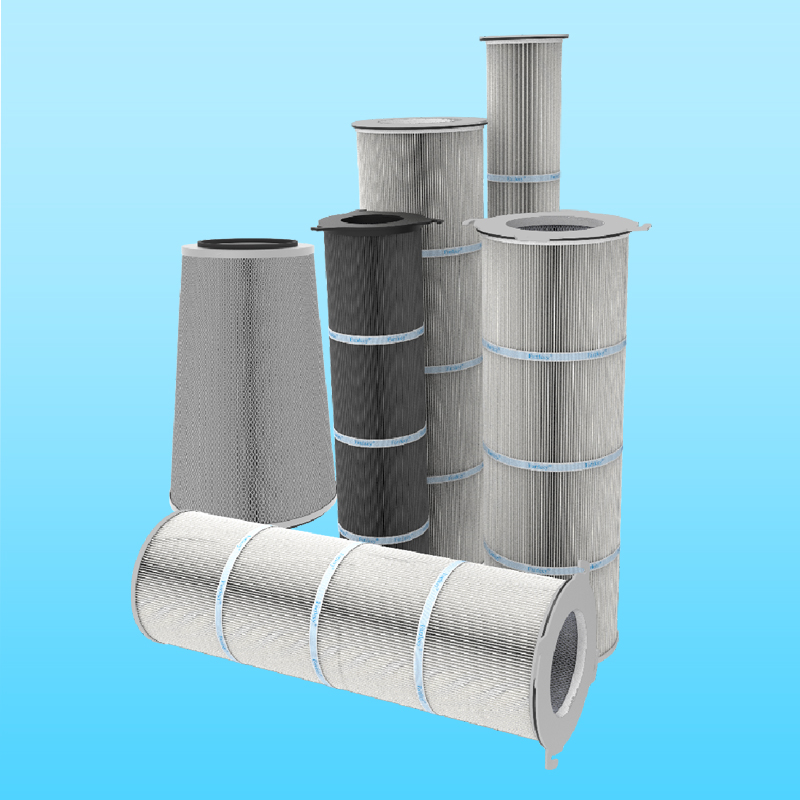

Description

Advantages

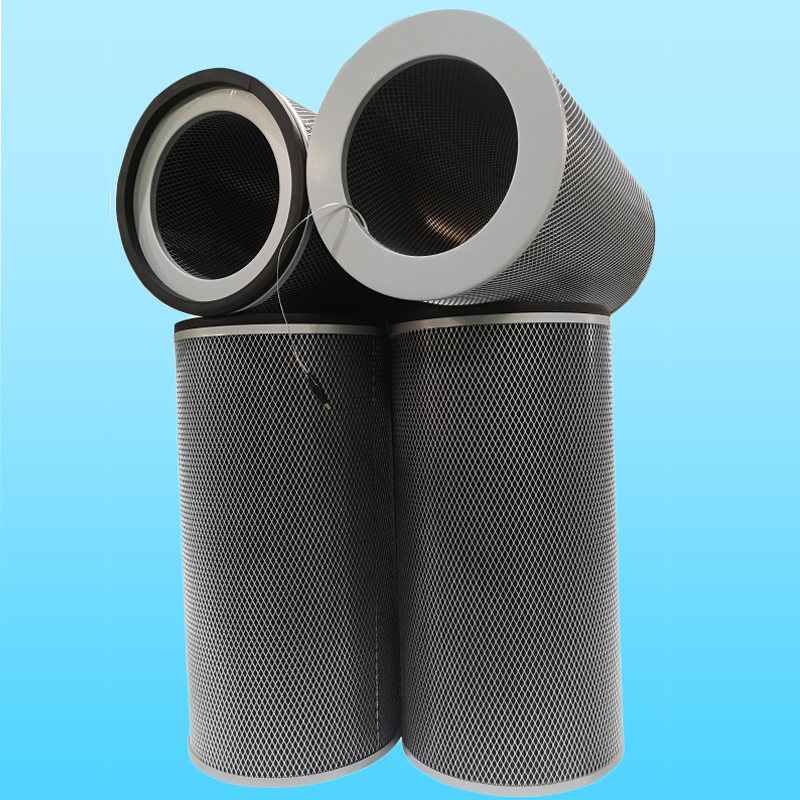

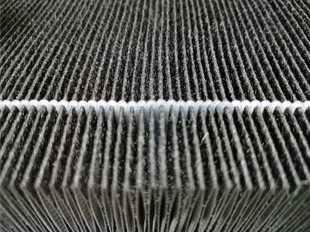

♦ Extreme Efficiency Carbon Fiber Blended Corrugated Media

In any case, the filter media material is the most influential factor in the efficiency of a dust filter cartridge. Unlike the most filter media of cellulose and synthetic fibers in the market, Farrleey’s extreme efficiency filter cartridge is made by carbon fiber blended corrugated media. It is a two-component material developed independently by Farrleey, which can be a thermally fused PTFE membrane. Compared with the Nanofiber treatment in the market, the thickness of carbon fiber blended corrugated media with anti-static PTFE membrane increases 20% and can reach 0.35mm to 0.4mm. This innovative treatment has greatly improved the efficiency of the dust filter cartridge in the following ways:

- Extreme efficiency (95% @0.3um, while other brands just can reach 70% to 80% for 0.3um)

- Low resistance (Air permeability is 200L/㎡.s, while other brands just can reach 120 to 150L/㎡.s)

- High tensile strength (CD>450N/5CM; MD>270N/5CM; Dry: 250/150N; Wet: 60N/5CM

- High moisture resistance

- High explosion-proof level

- Excellent flame retardancy

♦ Inside Glue Strap

The filter material will be glued inside pleats, and the spacing is uniformly between the pleats. It will help to lead the air to the cloth evenly to clean better.

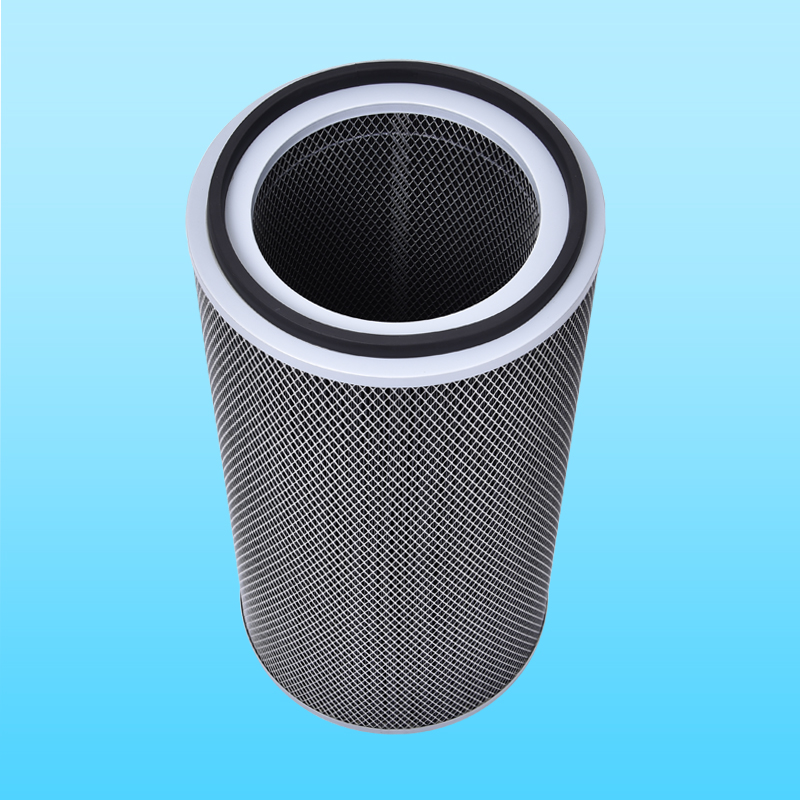

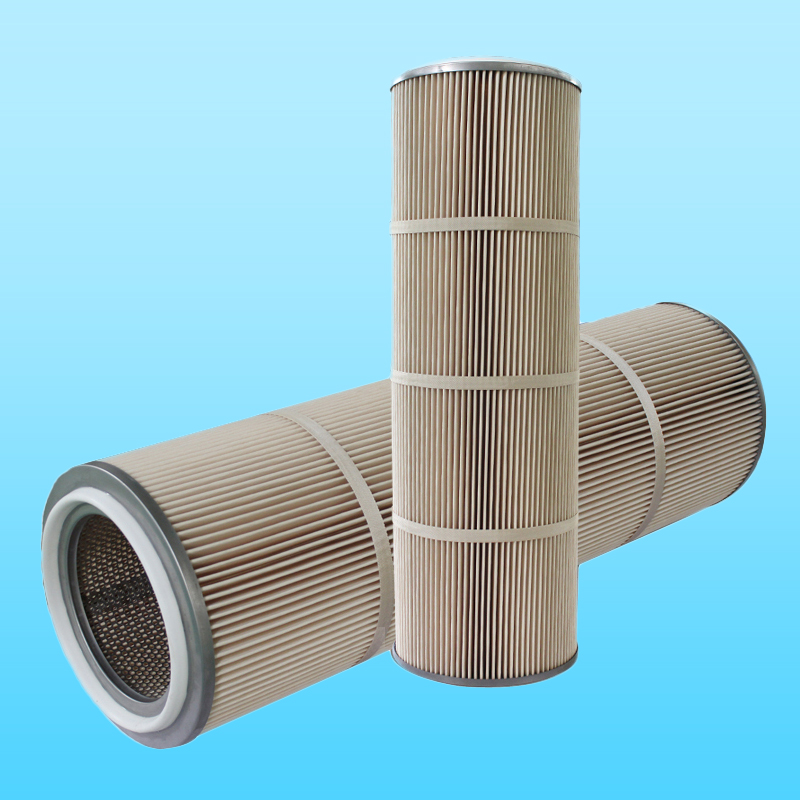

♦ High Strength Mesh

This new dust filter cartridge adopts rotating automatic occlusion reinforcement to ensure the integrity of the entire skeleton. The technology facilitates the integration of the inner web without splitting the joints and ensures high verticality. At the same time, the inner mesh is more beautiful and durable without repeated burrs.

♦ Super Adhesive

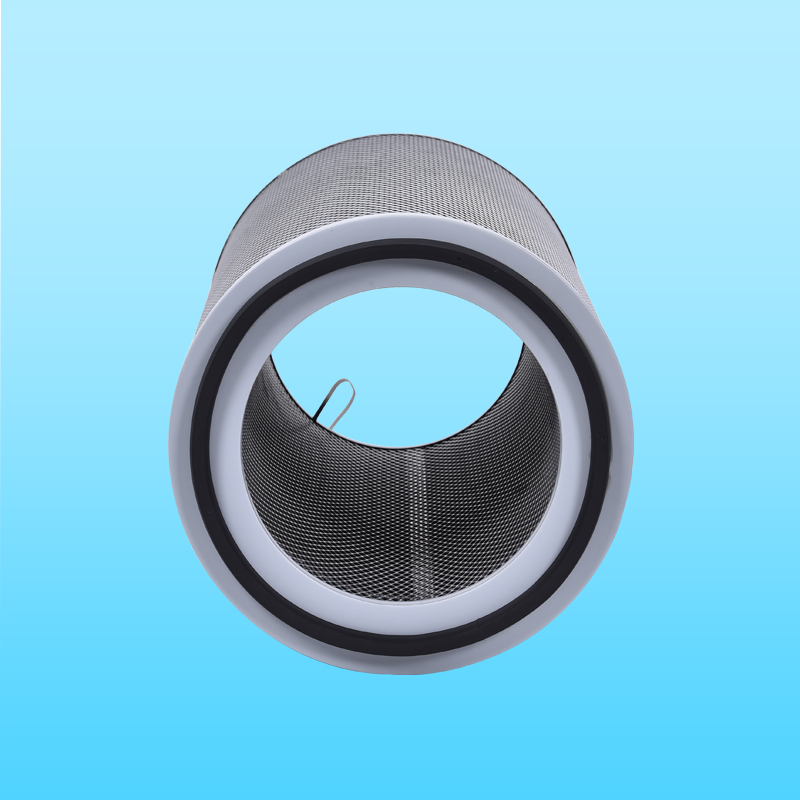

♦ Galvanized Steel/ Stainless Steel/ ABS Cap

It’s specially developed for the industries of new energy lithium battery, laser cutting, graphite, playing a significant role in the best dust collection system.